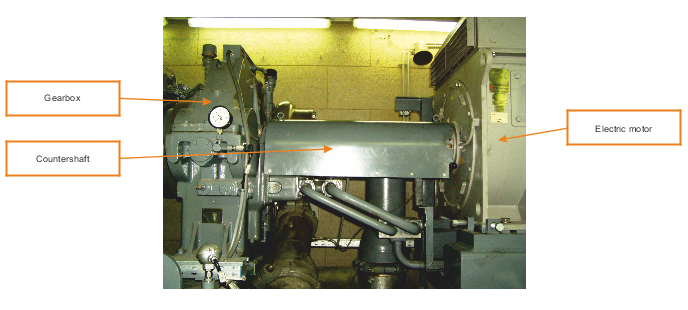

Fig.: Structure of a gearbox with countershaft

图: 带副轴的齿轮箱的驱动单元

Condition monitoring solution

状态监测解决方案

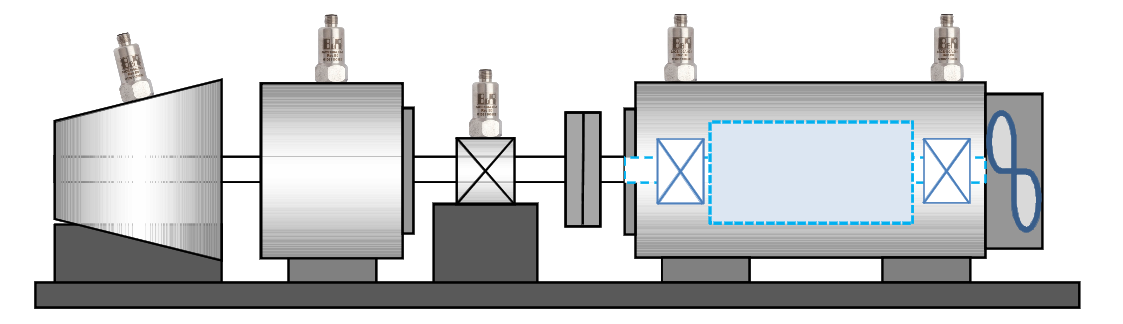

Fig.: System diagram - Gearbox with countershaft

图: 系统图 - 带副轴的齿轮箱的驱动单元

Sensor usage:

传感器的使用:

Number of sensors 传感器的数量 |

Usually 5 sensors. 2 sensors are sufficient for smaller and inflexibly coupled drive units. 通常为5个传感器。对于较小且刚性耦合的驱动单元,2 个传感器就足够了。 |

Sensor installation 传感器安装 |

Preferably vertical. Horizontal installation is also possible, if necessary. 最好是垂直安装。如果有必要,也可以水平安装。 |

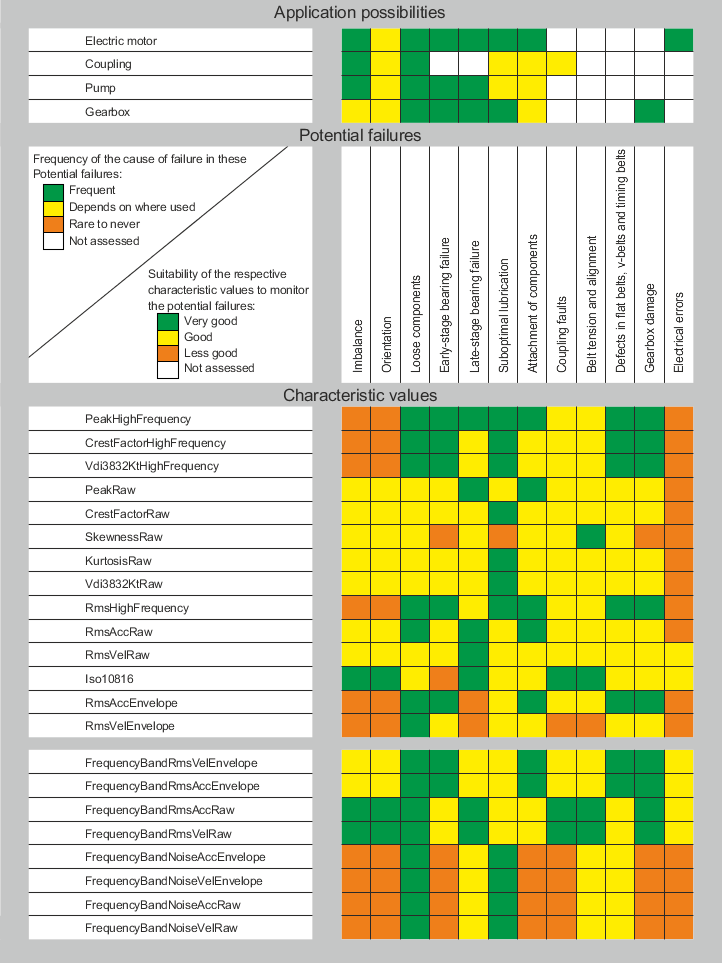

Gearbox with countershaft - Common problems:

带副轴的齿轮箱-常见问题:

For the meaning of individual characteristic values, see Characteristic values and Configuration.

各个特征值的含义,见 Characteristic values 和 Configuration。