It is possible to gain good insight into the condition of a machine or system by measuring the parameters associated with errors. This parameter data is used by different algorithms in the module to calculate the characteristic values. This method of forming characteristic values occurs continually and automatically. It requires little technical knowledge and is easy to use and implement. It is an easy way to check a machine for damage and error states.

Selecting suitable characteristic values and assessing them over a longer time frame is the basis for effective and successful monitoring of a machine, a process known as "trending". It enables multiple aggregates to be monitored with a relatively low need for technical measuring and a low demand on staff.

Simply setting basic limits as a warning is not enough. Instead, logical correlations with other parameters such as load or speed, or even the shape of the trend curve, are also required.

Characteristic values are thus gathered in the trend curve and compared with norms or values taken from available experience over a long period of time. This trend progression can be used to make a good assessment of the machine's condition. The way these factors change over time indicates whether the condition is worsening, i.e. if damage is beginning to occur.

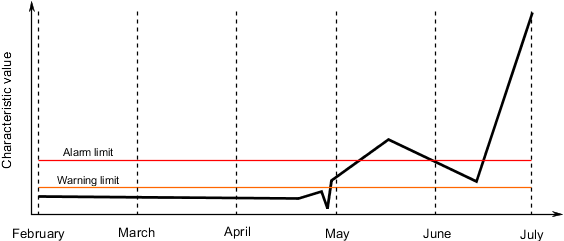

Recording the measured values in a diagram over a longer period of time shows the status of the characteristic values at the defined warning and alarm thresholds. If these thresholds are exceeded oscillation diagnostics gives the cause of the error so that appropriate maintenance measures can be taken.

通过测量与误差相关的参数,可以很好地了解机器或系统的状况。该参数数据由模块中的不同算法用于计算特征值。这种形成特征值的方法是连续和自动发生的。它只需要很少的技术知识,而且易于使用和实现。这是一种检查机器损坏和错误状态的简单方法。

选择合适的特征值并在较长的时间范围内对其进行评估,是有效和成功监测机器的基础,这个过程被称为 "趋势"。它能使多种集合体得到监测,对技术测量的需求相对较低,对工作人员的要求也不高。

仅仅设置基本限制作为警告是不够的。相反,还需要与其他参数(如负载或速度,甚至趋势曲线的形状)的逻辑相关性。

因此,特征值被记录在趋势曲线中,并与长期以来从现有经验中获取的规范或数值进行比较。这种趋势发展可以用来对机器的状况进行良好的评估。这些因素随时间变化的方式表明情况是否正在恶化,即是否开始出现损坏。

在较长时间内将测量值记录在图表中,显示出在定义的警告和报警阈值下的特征值的状态。如果超过了这些阈值,振荡诊断就会给出错误的原因,从而可以采取适当的维护措施。

Example: Trend curve for a characteristic value

举例: 一个特性值的趋势曲线