Cage damage

保持架损坏

Cage frequencies often occur in electric motors, especially where bearings with increased bearing play are used. If this is not used, oscillation of the cage often occurs. This is then reflected in increased operating noise.

保持架频率经常出现在电动机中,尤其是在使用轴承间隙增大的轴承的情况下。如果不使用这种方法,经常会发生笼条的振荡。这就反映在运行噪音的增加上。

Roller element damage

滚动元件损坏

Damage to rolling elements without damage to the outer or inner ring occurs extremely rarely; the individual features are therefore only given as examples.

If the roller element is damaged, an impact occurs either on the inner ring, outer ring or both. This makes it possible to detect damage to rolling elements caused by the rollover frequency or twice the frequency. For this reason, the harmonic should be included in the characteristic value calculation where possible to detect roller element damage.

在不损坏外圈或内圈的情况下损坏滚动元件的情况极为罕见;因此,单独的特征仅作为示例给出。

如果滚动元件损坏,内圈、外圈或两者都会受到冲击。这样就有可能检测到由滚动频率或两倍的频率引起的滚动元件的损坏。因此,在可能的情况下,应将谐波包括在特征值计算中,以检测滚动元件的损坏。

For the damage symptoms, see Typical outer and inner ring damage.

有关损坏症状,见Typical outer and inner ring damage。

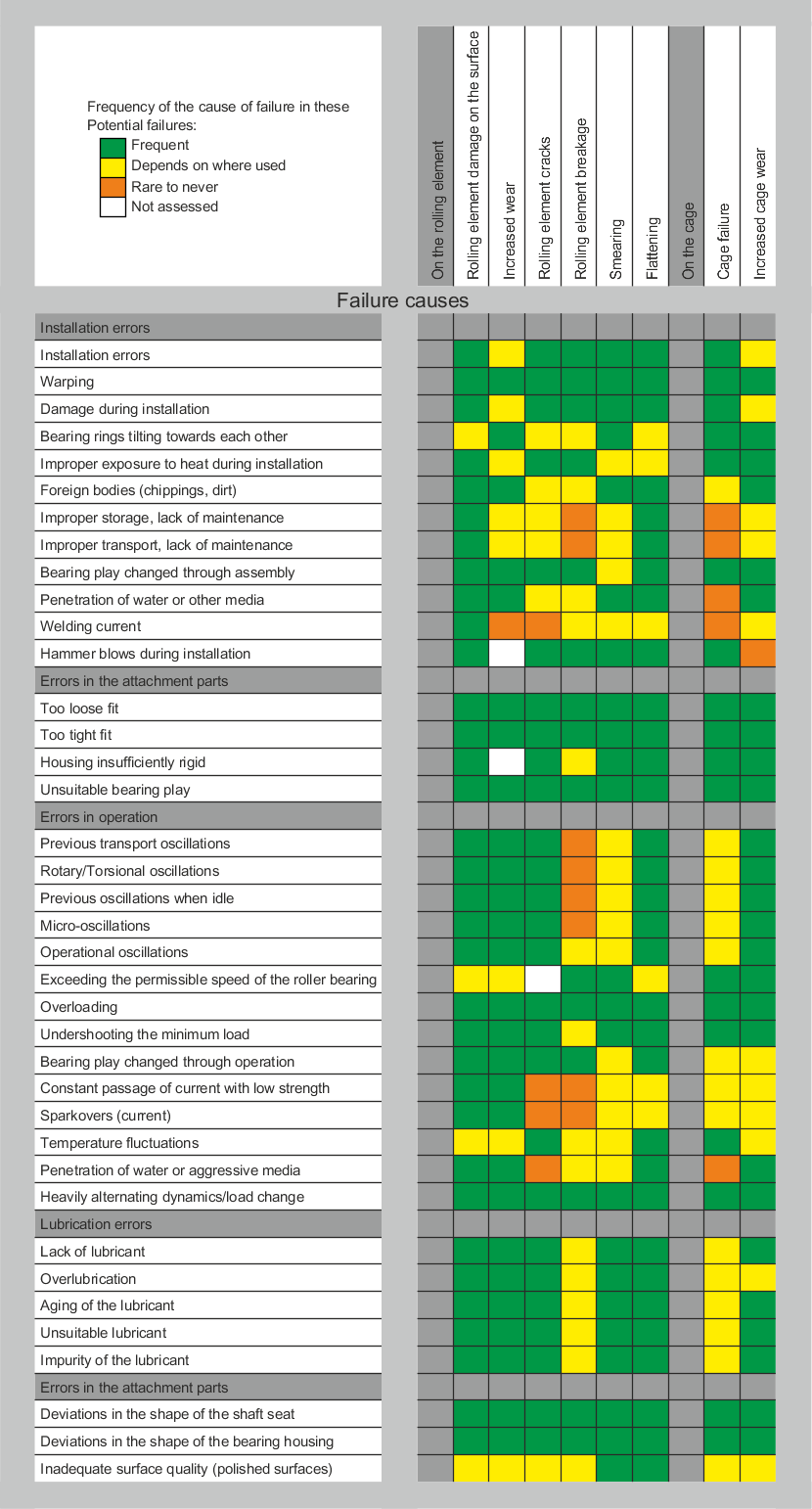

Fig.: Frequency of failure indicators on roller bearings

图: 滚动轴承的故障指标频率

For the meaning of individual characteristic values, see Characteristic values and Configuration.

关于各个特征值的含义,见Characteristic values 和 Configuration。

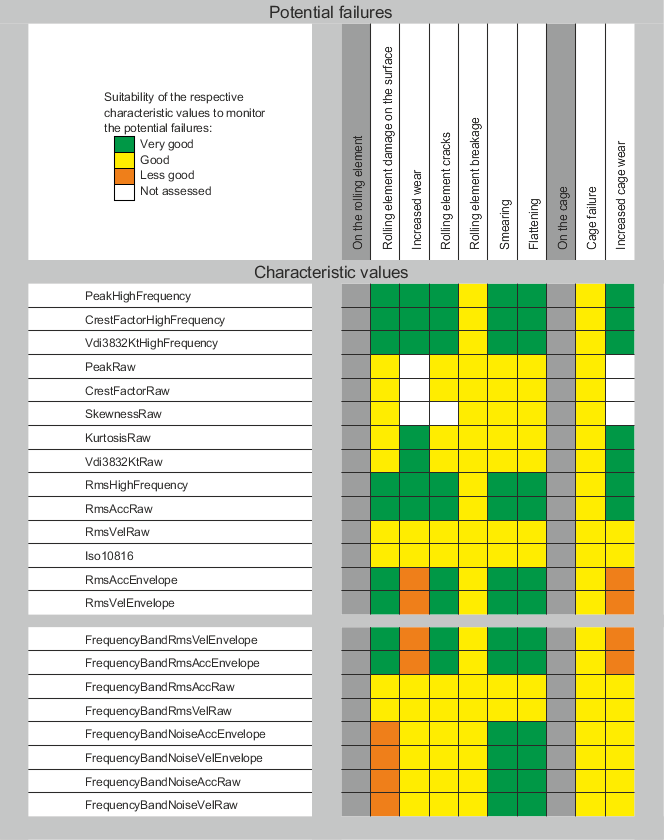

Fig.: Frequency of failure indicators on roller bearings

图: 滚动轴承的故障指标频率

For the meaning of individual characteristic values, see Characteristic values and Configuration.

关于各个特征值的含义,见 Characteristic values 和 Configuration。