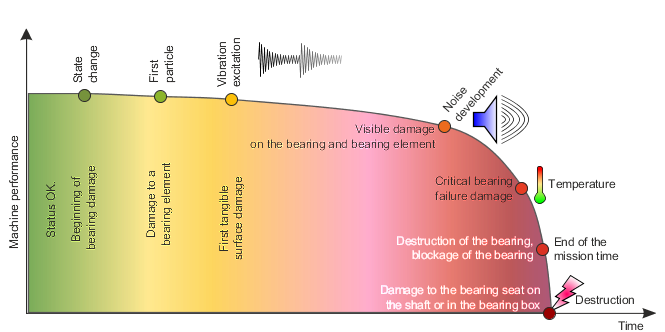

Explaining damage development with a roller bearing example 以滚子轴承为例解释损伤发展

The majority of bearing damage develops slowly and usually without being noticed. In many cases, it is only once the damage is more advanced that irregular running and unusual operating noises indicate bearing damage. This points to material fatigue, e.g. chipping or altered radial clearance through wear.

If the damage is so advanced that it can be detected without measuring equipment, spontaneous failures such as blockages and breakage of the bearing housing components often occur.

大多数轴承损坏的发展是缓慢的,通常不会引起注意。在许多情况下,只有当损坏更严重时,不规则的运行和异常的运行噪音才表明轴承的损坏。这表明材料疲劳,例如由于磨损而产生的碎屑或径向间隙变化。如果损坏过于严重,则无需测量设备即可检测到,往往会出现自发的故障,如轴承座部件的堵塞和断裂。

Fig.: Illustration of the damage chain and the development of damage over time

图.: 损伤链损坏随时间发展的图示

The damage chain illustrated in the image above presents condition monitoring as an important tool in the condition-based operation and maintenance of a system.

It is possible to draw conclusions about the condition of the machine or its components from the parameters recorded by the sensors. Deterioration of the condition of components or system parts becomes apparent through the detection and observation of their condition, the consideration of the trend and, if necessary, through the detailed analysis of the measurement data obtained. Based on this, targeted measures can be put in place for maintenance.

Condition monitoring is a suitable option under the following conditions:

•Measurable parameters that correlate with a failure need to be identified and selected.

•The failure cannot be prevented by redesign or altered usage.

•Events lead to failures that occur randomly.

•Sufficient warning time must be given in advance before a function fails.

上图中所示的损伤链将状态监测作为基于状态的系统操作和维护的重要工具。

从传感器记录的参数中可以得出关于机器或其部件状况的结论。通过检测和观察组件或系统部件的状况,考虑其趋势,并在必要时通过对获得的测量数据进行详细分析,组件或系统部件的状况恶化就会变得明显。在此基础上,可以采取有针对性的措施进行维护。

在以下条件下,状态监测是一个合适的选择:

•需要识别和选择与故障相关的可测量参数。

•该故障无法通过重新设计或改变使用方式来预防。

•事件会导致随机发生的故障。

•在功能失效之前,必须提前给出足够的警告时间。

The consideration of condition monitoring resources is not permitted to be limited to the consideration of the recording of operating conditions alone but should be integrated into this as part of a general asset management strategy. In order to manage this, all types of condition monitoring and industrial diagnostics should be combined into an overall strategy.

For a failure-oriented operational mode ("reactive maintenance"), components are only replaced if they can no longer fulfill their function. For planned operation ("preventive maintenance"), components are replaced at a certain point in time – regardless of their current condition.

For condition-based maintenance, the area where maintenance is planned can be significantly isolated while reducing the risk of failure at the same time.

对状态监测资源的考虑不允许仅仅局限于对运行状况记录的考虑,而应将其作为一般资产管理战略的一部分纳入其中。为了管理这一点,所有类型的状态监测和工业诊断都应该结合到一个整体战略中。

对于以故障为导向的运行模式(“被动性维护”),只有当部件无法再履行其功能时,才会更换部件。对于计划运行(“预防性维护”),无论部件的当前状况如何,都会在某个时间点更换部件。

对于基于状态的维护,计划维护的区间可以被大大隔离,同时降低故障风险。

Advantages 优势 |

Disadvantages 劣势 |

|

|---|---|---|

Reactive maintenance 被动性维护 |

- Utilization of the wear reserve - 利用了磨损储备 - No costs during the period of use - 在使用周期内没有成本 |

- Unexpected failure - 意外故障 - Consequential damage - 间接损害 - High downtime costs - 高停机成本 - Low operational safety - 运行安全性低 |

Preventive maintenance 预防性维护 |

- Can be planned well - 可以很好地规划 |

- No utilization of the wear reserve - 不利用磨损储备 - Increased risk of failure after maintenance - 维护后故障风险增加 - Repair costs - 维修费用 |

Condition-based maintenance 基于状态的维护 |

- Early recognition of problems - 及早发现问题 - Downtime can be planned - 可以计划停机时间 - Utilization of the wear reserve - 利用磨损储备 - High operational safety - 运行安全性高 - Avoidance of consequential damage - 避免间接损害 |

- Dealing with the issue - 处理问题 - Investment costs - 投资成本 - Additional costs for equipment to measure condition - 测量状态的设备的额外费用 |