With flat belts and V-belts, torque is transferred between the belt and the pulley through the contact surface. Belt drives are not very sensitive with regard to alignment but nevertheless lead to vibration development and above all to increased wear and energy consumption if the deviation is too high.

对于平带和三角带,扭矩通过接触表面在皮带和皮带轮之间传递。皮带传动对对中不是很敏感,但还是会导致振动的产生,尤其是如果偏差太大,会增加磨损和能源消耗。

Failure mode 故障类型 |

Frequency in raw signal spectrum 原始信号频谱中的频率 |

Frequency in envelope spectrum 包络谱中的频率 |

Comment 解释 |

|---|---|---|---|

Defective belt 缺陷的皮带 |

1 x fr, 2 x fr, 3 x fr ... |

1 x fn1, 1 x fn2, 1 x fr |

Belt frequencies usually occur in both spectra. 皮带频率通常出现在两个频谱中。 |

fr |

... Belt speed ... 皮带速度 |

fn1 |

... Nominal speed of shaft 1 ... 轴1的标称速度 |

fn2 |

... Nominal speed of shaft 2 ... 轴2的标称速度 |

Poorly aligned or incorrectly tensioned belts can also cause severe stress on the bearing points. The increased vibration also causes heavier wear on belts and pulleys.

The vibrations are clearly identifiable at the bearing points of the individual shafts.

对齐不良或张紧不正确的皮带也会在支承点上造成严重的应力。振动的增加也会导致皮带和滑轮的磨损加剧。

在各个轴的轴承点处可以清楚地识别到振动。

Failure mode 故障类型 |

Frequency in raw signal spectrum 原始信号频谱中的频率 |

Frequency in envelope spectrum 包络谱中的频率 |

Comment 解释 |

|---|---|---|---|

Misalignment of belt 皮带不对中 |

1 x fn, 2 x fn 1 x fr |

1 x fn |

If the belts strike against the pulley laterally, impacts can also occur with speed and belt frequency. 如果皮带横向撞击皮带轮,则速度和皮带频率也会发生冲击。 |

fn |

... Nominal speed ... 标称速度 |

fr |

... Belt speed ... 皮带速度 |

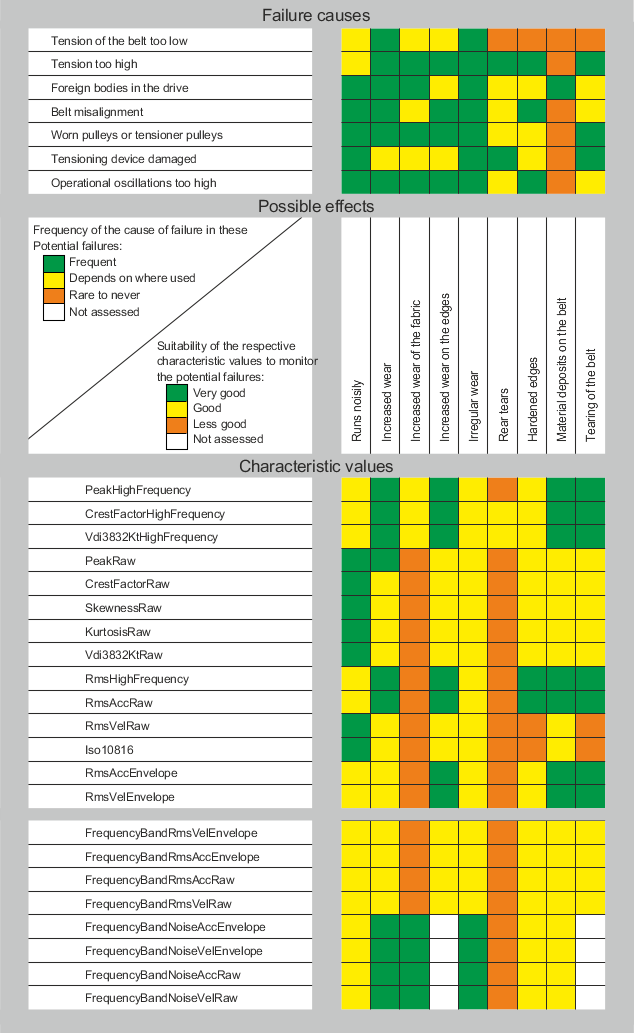

Fig.: Failure causes and effects of belt damage in flat belts and V-belts

Fig.: 平带和三角皮带皮带损坏的故障原因和影响

For the meaning of individual characteristic values, see Characteristic values and Configuration.

各个特征值的含义,见 Characteristic values 和 Configuration。