In DIN 3960, axial distance errors are defined as a deviation between the target/actual value.

An error that changes the distance between two axes changes the way the gears mesh and has a negative effect on the overlap ratio.

Even small pitch errors lead to increased noise in the gearbox.

在DIN 3960中,轴向距离误差被定义为目标值/实际值之间的偏差。

改变两个轴之间距离的误差会改变齿轮的啮合方式,并对重叠率产生负面影响。

即使是很小的间距误差也会导致齿轮箱的噪音增加。

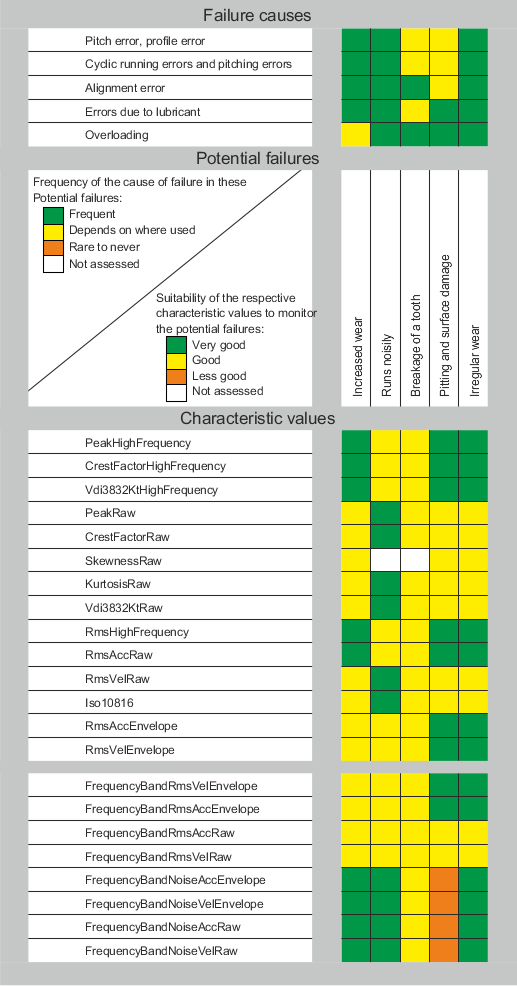

Fig.: Frequency of failure indicators for gearbox damage

图: 齿轮箱损坏的故障指标频率

For the meaning of individual characteristic values, see Characteristic values and Configuration.

各个特征值的含义,见 Characteristic values 和 Configuration。