In many cases, not enough is known about the actual behavior of a machine during operation, in particular when there is damage.

To make a reliable statement about its condition, the chronological sequence of the characteristic values (characteristic value trend) must also be used when making the assessment.

In the progression of the trend, the "Normal condition" is the starting point. The reference level (normal level) is the level of the characteristic value as set in the normal condition.

Changes in the trend are observed with the normal condition as the starting point. When there is damage, the relevant characteristic values in each case generally increase, although a decrease can also be an indication of a problem in the system.

In order to assess trends accurately, it is essential that the characteristic values of the oscillations are always recorded under the same operating conditions and always classified in the same way. In particular, the speed and load ratio have a strong effect on the characteristic values. Increases in trends under differing operating conditions cannot necessarily be a sign of a change in the actual condition. In many cases, trend observation can assist in monitoring the condition of the machine and bearings.

在许多情况下,对机器在运行过程中的实际行为了解不够,特别是在有损坏时。

为了对其状况做出可靠的说明,在进行评估时还必须使用特征值的时域序列(特征值趋势)

在趋势的发展过程中,"正常状态 "是起点。参考水平(正常水平)是在正常状态下设定的特征值的水平。

以正常情况为起点观察趋势的变化。当出现损坏时,每种情况下的相关特性值一般都会增加,尽管也可能表明系统存在问题。

为了准确评估趋势,必须在相同的操作条件下始终记录振荡的特征值,并以相同的方式进行分类。特别是,速度和负载率对特征值有很大的影响。在不同的操作条件下,趋势的增加不一定是实际条件变化的标志。在许多情况下,趋势观察可以帮助监测机器和轴承的状况。

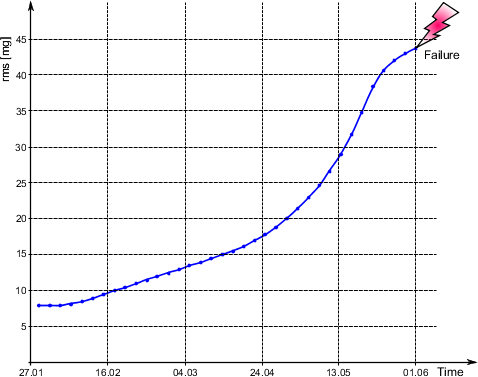

Fig.: Typical trend progression

图: 典型的趋势发展

The first and second derivatives of the damage progression trend line can provide good information about how badly a component is damaged.

损伤发展趋势线的一阶和二阶导数可以提供关于部件损伤严重程度的良好信息。

Example

举例

This example will use the first and second derivative to determine the best time for repairs. The maximum service life will be taken into account when selecting a time to perform a replacement. The possibility of lowered production quality is not taken into consideration.

Various times for performing a replacement can be selected by referring to the trend progression.

本例将使用一阶导数和二阶导数来确定最佳维修时间。在选择进行更换的时间时,将考虑最大使用寿命。不考虑生产质量下降的可能性。

通过参考趋势的发展,可以选择各种要执行替换的时间。

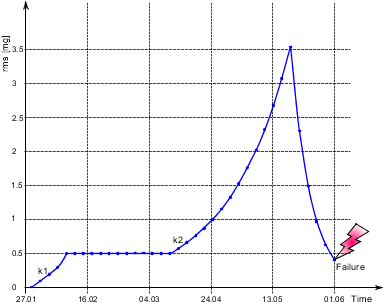

•k1 = First increase. Very conservative, service life is wasted.

k1 = 第一次增加。非常保守,浪费使用寿命。

•k2 = Second increase. Good compromise between conservative and optimal.

k2 = 第二次增加。保守和最优之间的良好折衷。

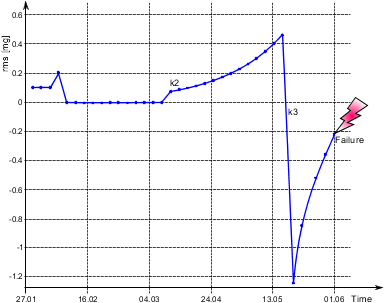

•k3 = Drop in second derivative. Optimal utilization of service life.

k3 = 二阶导数的下降。使用寿命的最佳利用率。

Information:

注意:

This example of derivative usage is not permitted to be used as a rule in your own applications.

这个导数使用的例子不允许在你自己的应用中作为一个规则使用。

First derivative

一阶导数

Fig.: First derivative of the trend progression

图: 趋势发展的一阶导数

Second derivative

二阶导数

Fig.: Second derivative of the trend progression

图 趋势发展的二阶导数