During operation, a number of different factors can cause machine parts to fail to align or stop aligning with each other.

Shafts should rotate around a linear axis at the coupling positions, so that the restoring forces at the coupling position and the loading forces in the bearings are kept as low as possible. Misalignment causes increased vibrations and wear.

Misalignment usually consists of a parallel and an angular misalignment. In the event of a severe parallel misalignment, strongly increased values can be observed in the area of double speed.

在操作过程中,许多的因素可能会导致机器部件无法对中或失去对中。

轴应在联轴器位置绕直线轴旋转,这样联轴器的恢复力和轴承中的负载力就会保持在尽可能低的水平。不对中会导致振动和磨损增加。

不对中通常包括平行错位和角度错位。在出现严重的平行错位的情况下,可以在双倍速度的区域观察到大幅增加的值。

Failure mode 故障类型 |

Frequency in raw signal spectrum 原始信号频谱中的频率 |

Frequency in envelope spectrum 包络谱中的频率 |

Comment 解释 |

|---|---|---|---|

Misalignment in coupling 联轴器未对准 |

1 x fn, 2 x fn (sometimes 3 x fn, 4 x fn) (有时会在 3 x fn, 4 x fn) |

- |

With parallel misalignment, usually only "1 x fn" occurs. 在平行错位的情况下,通常只有 "1 x fn" 。 |

fn |

... Nominal speed ... 标称转速 |

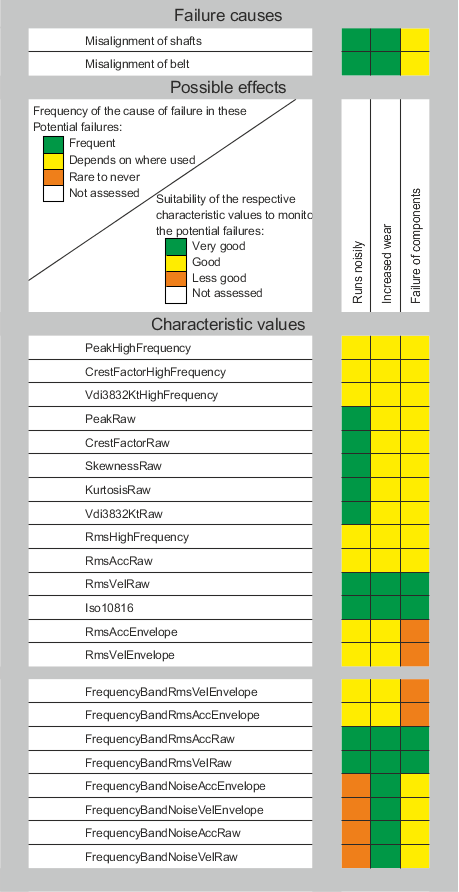

Fig.: Failure causes and effects of an alignment failure

图: 对中故障的原因和影响

关于各个特征值的含义,见Characteristic values 和 Configuration。