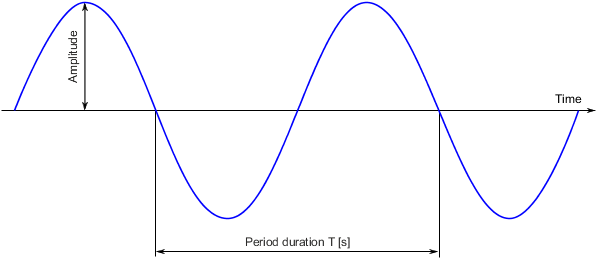

OSCILLATIONS ARE FORMS OF MOVEMENT THAT OCCUR VERY FREQUENTLY IN NATURE. HARMONIC OSCILLATION IS THE THIRD BASIC TYPE OF FORM OF MOVEMENT ALONGSIDE UNIFORM MOVEMENT AND UNIFORM ACCELERATING MOVEMENT. AN OSCILLATION OR VIBRATION IS A CYCLIC, I.E. REPETITIVE SIMULTANEOUS MOVEMENT OF A STRUCTURE IN ITS REST OR EQUILIBRIUM POSITION.

振荡是自然界中经常发生的运动形式。谐波振荡是与匀速运动和匀加速运动并列的第三种基本运动形式。振荡或振动是一种循环运动,即结构在其静止或平衡位置的重复性的同时运动。

FIG.: ILLUSTRATION OF A BASIC OSCILLATION

图: 基本振荡图示

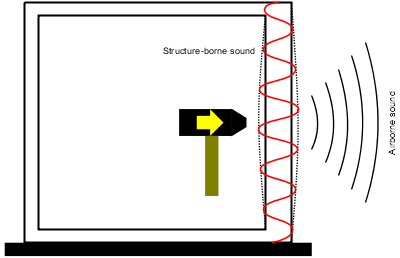

IF A FIXED MEDIUM IS STIMULATED BY AN IMPACT, STRUCTURE-BORNE SOUND SPREADS THROUGHOUT IT. THIS CONSISTS OF ADDITIONAL FREQUENCIES WHICH ARE DETERMINED BY THE SHAPE OF THE STRUCTURE AND THE MATERIAL IT IS MADE FROM (E.G. GONG OR CONCRETE BLOCK).

A PORTION OF THE STRUCTURE-BORNE SOUND ENERGY IS CONVERTED INTO AIRBORNE SOUND THROUGH THE SURROUNDING ATMOSPHERE.

如果固定介质受到冲击的激励,结构传播的声音会在整个介质中传播。这包括额外的频率,这些频率由结构的形状和材料决定(如锣或混凝土块)。

一部分结构声能通过周围大气转换为空气传播的声音。

FIG.: PROPAGATION OF STRUCTURE-BORNE SOUND

图: 结构传声的传播

THE MEASUREMENT AND SUBSEQUENT ANALYSIS OF THE MECHANICAL OSCILLATIONS ON STATIONARY AND ROTATING PARTS OF MACHINES, SUPPORT STRUCTURES AND PIPELINES HAS BECOME ACCEPTED AS TECHNICALLY POSSIBLE WITH PRACTICALLY APPLICABLE MONITORING PROCEDURES.

THE ABSOLUTE BEARING OSCILLATION IS MEASURED ON THE HOUSING OF THE MACHINE AND INVOLVES THE MOVEMENTS OF THE HOUSING IN RELATION TO A FIXED REFERENCE POINT IN THE ROOM.

MECHANICAL OSCILLATIONS ARE A GOOD PARAMETER FOR DETECTING INITIAL DEFECTS AND DAMAGE AND CAN BE USED FOR MACHINE DIAGNOSTICS.

THERE ARE NUMEROUS OVERLAPPING CAUSES FOR OSCILLATIONS. THE SIZE (AMPLITUDE) OF THE OSCILLATION DEPENDS ON SEVERAL FACTORS SUCH AS ATTENUATION THROUGH JOINTS OR GREASE, THE RIGIDITY OF THE COMPONENT, THE HOUSING AND FOUNDATIONS AND MUCH MORE.

DAMAGE IS ALWAYS A CONSEQUENCE OF STRESS. IF CYCLIC STRESS OCCUR, IT CAN BE IDENTIFIED BY ITS EXCITATION FREQUENCY AND INTENSITY.

对机器、支撑结构和管道 的 固定和旋转部分的机械振荡的测量和后续分析,已经被认为在技术上是可行的,并具有实际适用的监测程序。

绝对的轴承振荡是在机器的外壳上测量的,涉及到外壳相对于区域内固定参考点的运动。

机械振荡是检测初始缺陷和损坏的一个良好参数,可用于机器诊断。

摆动有多重原因。振荡的大小(振幅)取决于几个因素,如受接头或油脂的衰减影响、部件的刚性、外壳和地基等等。

损坏总是应力的结果。如果发生周期性应力,可以通过其激励频率和强度来识别。

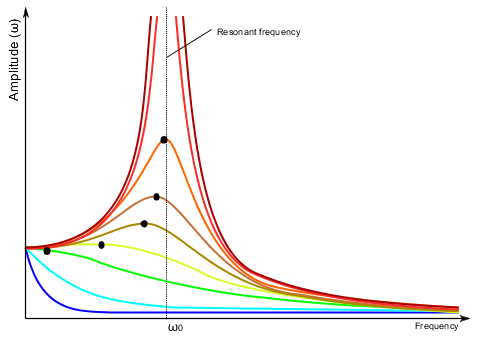

RESONANT FREQUENCY

共振频率

EVERY MACHINE HAS WHAT ARE KNOWN AS RESONANT FREQUENCIES. THESE MUST BE OBSERVED DURING OPERATION SINCE WITH THESE FREQUENCIES THE AMPLITUDE OF THE OSCILLATION INCREASES DRAMATICALLY, PUTTING STRAIN ON THE MECHANICAL COMPONENTS. IF HARMONIC OSCILLATIONS OCCUR FOR A LONG TIME IN PROXIMITY TO THE RESONANT FREQUENCY, THIS CAN LEAD TO A SO-CALLED "RESONANCE CATASTROPHE", WHICH CAUSES THE DESTRUCTION OF THE AFFECTED PART.

每台机器都有固有的的谐振频率。在运行过程中必须观察这些频率,因为这些频率的振荡幅度会急剧增加,给机械部件带来压力。如果谐波振荡在靠近共振频率的地方发生很长时间,就会导致所谓的 "共振突变",从而导致受影响部件的破坏。

FIG.: INCREASE OF THE AMPLITUDE IN PROXIMITY TO THE RESONANT FREQUENCY

图: 靠近谐振频率的振幅增加